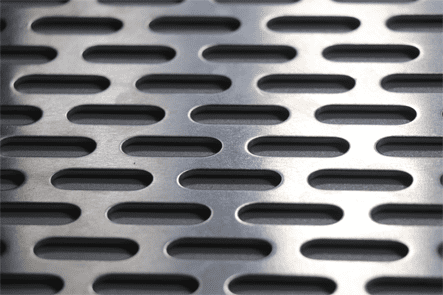

Perforated Aluminum Sheet, Panel and Plate Service

The most effective way to cut punctured metal sheets is with

a guillotine. We understand most DIYers don't have a guillotine in the shed, so

the thing we prescribe is connecting with a fabricator in your space. They

ought to have a guillotine and will be glad to make a couple of cuts for you. Perforated

metal, otherwise called punctured sheet, punctured plate, or punctured screen,

is sheet metal that has been physically or precisely stepped or punched

utilizing CNC innovation or at times laser slicing to make various openings

sizes, shapes, and examples.

These minimal expense choices incorporate sled and etch

compound cuts or hacksaws. Green or red metal clips, or hand shears, can cut sheets

along bends as well as straight lines, yet they will mutilate the two edges

while making inner cuts on a piece of aluminum sheet. They are an

unquestionable requirement for any total instrument assortment in view of their

flexibility and their capacity to cut with accuracy and detail. However long

you have the legitimate insurance and the right cutting plates, you can utilize

a Dremel device to cut pretty much anything, including aluminum. Check

this

A punctured Aluminum Sheet is a sheet item that has been

punched with a wide assortment of opening sizes and examples giving a stylish

allure. Punctured Aluminum Sheet offers reserve funds in weight, entry of

light, fluid, sound, and air, while giving an improving or elaborate effect. A

punctured metal sheet has an underlying strength that is better than many

structure materials. As per the Industrial Perforators Association, circular

openings are organized in a standard 60-degree three-sided design going from.

Punctured metal can be utilized for primary and enlivening

applications in engineering and configuration, including balustrades,

exteriors, steps, and screens, and its attributes consider imagination with

light, sound, and visual profundity. Punctured metal can be utilized to manage

light and ventilation inside a space.

The best grating grains to cut and crush aluminum compounds

incorporate aluminum oxide, silicon carbide, mixes of aluminum oxide, silicon

carbide, zirconia, and earthenware. Since most aluminum compounds are

outstandingly delicate, very wear-safe zirconia and fired grating grains can be

over the top excess. The change in the general climate has been reinforced,

particularly in the plan of a few business places and private structures.

Furthermore, building materials are turning out to be increasingly bountiful

and novel, a solitary material isn't sufficient to meet the plan needs. The

utilization of metal, wood, and stone.

Comments

Post a Comment